The Laser

my wife's hair

my son's head

The letters LASE on the picture above have half the hight of a hairs diameter: ~ 30 µm.

I built this machine a couple of years ago from scrapped parts, mostly from auctions and scrap yards. The only new components were the UHU servo controllers from Uli Huber, the aluminum profiles for the frame and the focus lens from Edmund Optics.

The Laser is a water cooled UV laser with a wave length of 355 nm. It is a q-switched diode pumped Nd:YAG laser with frequency tripling. The average output power is < 2W. The pulses have a width of some nanoseconds and several kilowatts of power. The ablation process for many materials is a photo chemical process rather than a thermal process. For my applications I use average powers far below 1 W. 1.3 W is sufficient for cutting 0.3 mm of steel!

I needed to refurbishe the laser by replacing the pump diodes.

The xy-stage is of very high precision.

The machine is controlled by a Trocen Anywell AWC708C laser controller, designed for CO2 lasers, which I had to modify for usage in combination with the Nd:YAG laser. It's a stand alone controller. The software LaserCAD allows communication between the computer and the controller and to draw geometry, add text and images, although I primarily use LibreCAD under linux for these tasks.

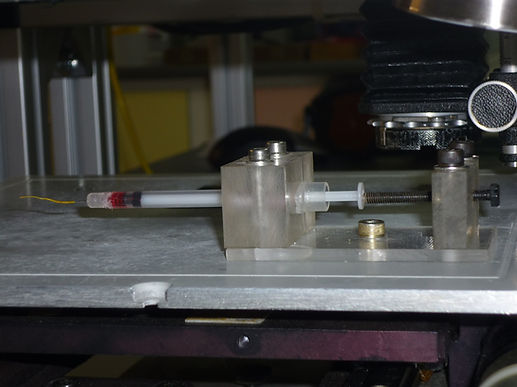

The Droplet Injector

The droplet injector is mounted under the microscope and serves for injecting the droplets in the gap of 0,23 mm between the coated glass plates. As I already mentioned, great care has to be taken, not to damage the coatings. The insulin syringe comes with a cannula of 0.3 mm in diameter, that is grinded to a diameter of 0.2 mm. On top of this I put a PTFE tubing, made from the insulation of a piece of wire wrap. This piece of insulation is stretched to its maximal achievable length and has a diameter of 0.2 mm at its end.

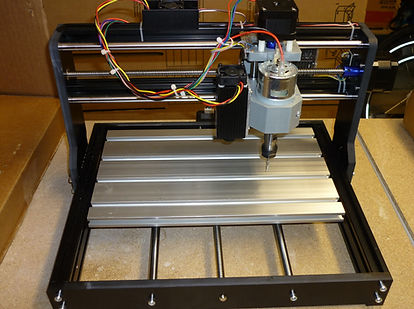

CNC 3018 Milling Machine

This machine comes as a kit and reminded me on a well-known Swedish furniture store :-). I us it for milling the outer contour of the PCB.

On the left side of the spindle I attached a blue laser with 5.5 W of power, what really is a lot!

But honestly, there is no serious application, I could use this laser for, because it is not pulsed and has a low beam quality.

The Laminator

The Spin Coater

The spin coater is made from a CPU fan